Examples of chemical recycling companies:

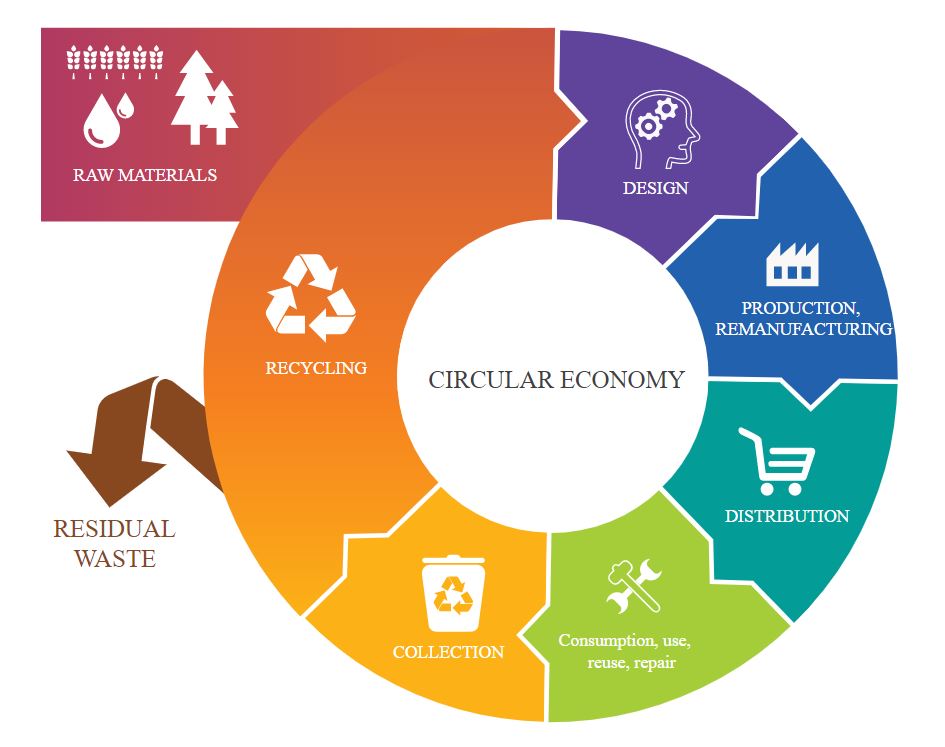

Multiple chemicals disrupt the circular economy as they are banned or hazardous. Hazardous chemicals such as brake fluid, solvents, and pesticides in waste material create an extra obstacle for the shift to a fully circular economy. Such chemicals make the cost of recycling much higher and make the recycling process more complex. The issue is, many of these chemicals play pivotal roles in products like electronics and medical equipment because they provide key functionality to the products.

Chemical recycling can create value out of plastics that were previously not recyclable. This is done by breaking down the plastics, which then offer the building blocks for new high-quality polymers.

Around the world, it is estimated 2 billion people lack access to regular waste collection and 3 billion lack access to proper waste disposal facilities. This leads to a huge amount of solid waste being leaked into the environment.

Some reports suggest that in 2016, only 12% of 260 million tonnes of plastic waste was recycled. But it is possible for 50% of plastics and chemicals worldwide to be reused or recycled by 2030. In order, to achieve this level of growth; a significant increase in infrastructure, more efficient mechanical recycling, and a roll-out of chemicals recycling infrastructure is needed.

In addition, these developments would require a large investment – a high estimate forecast between $15 and $20 billion per year.

In Europe, it is estimated that 40% of plastics are recycled, however, the effective recycling rate is only 10-15% and only 5% of the plastics’ original value is kept in the economy.

Firstly, the majority of plastics made are still not fully designed to be recycled. Although many companies claim their plastics and packaging is 100% recyclable, more often than not, this is not the full story. Moreover, confusion and issues within the recycling chain mean plastics that are meant to be recycled are often not.

These issues are preventing the circular economy and hindering our ability to be a cleaner world.

From January 2021, companies across the EU that produce products containing substances of very high concern will have to submit their waste data to a new system called Substances of Concern In Products (SCIP) that is being overseen by the European Chemicals Agency.

This system that has been introduced is not just about understanding the level of recycling. It also aims to boost innovation and development in the chemicals industry and help a shift to safer and less hazardous alternatives. This change aims to lead to a world where all plastics can be recycled easily and efficiently because all plastics and products will be free of hazardous chemicals.

There are multiple different technologies used for the recycling of different plastics and chemicals depending on their chemical structure, grade quality, and functional use.

Chemical companies like BASF and Agilyx are performing constant research and development in their industry. These companies are always looking to create new alternative chemicals and materials which can be used in products around the world but are more sustainable, easily recycled, and less damaging to the environment than the current options. By developing new chemicals which are easily recycled it can streamline the recycling process. The development these chemical companies are looking to make will not only help the sustainability of the economy but also opens the opportunity for investments.

Top recycling countries around the world:

| Germany Germany are the top recycling nation in the world – 68% of waste is recycled. Their recycling policies have been in place since the 1990s and they have built robust recycling infrastructure. This is a result of their early awareness to climate change. The system they have in place is highly efficient and used by the large majority of their citizens resulting in an extremely high recycling rate for their waste. |

Austria Austria’s effective waste-management system simply bans certain items from entering landfill. Any product that has a total organic carbon emission rate of more than 5% is prohibited from entering landfill. They also use a compliance service model called Altstoff Recycling Austria (ARA) that helps producers of waste to monitor their levels of business waste so that they can meet ‘Producer Responsibility’ obligations. The importance of recycling is also evident in Austria’s educational programmes. |

| South Korea South Korea’s system called ‘Jongnyangje’ is known for its efficiency. Using a colour-coded system and being strictly enforced, South Korea has been able to achieve a very high recycling rate. Fines and penalties are also mechanisms used to control and influence compliance to the system. |

Wales Wales are ahead of the rest of the UK at recycling with around 64% of waste being recycled. The nation has set a target of sending zero waste to landfill by 2050. Wales have achieved this impressive recycling rate through local authority municipal waste management measures. For example, the range and volume of material collected for recycling is closely monitored as well as restricting the volume of recyclable material placed in ‘non-recycling’ collections. |

| Switzerland Switzerland run a ‘polluter pays’ system. This means that businesses and people pay for the waste they produce that is unable to be recycled. This has an impact on both manufacturers and the public which plays a role in their success. In addition, Switzerland tax the bin bags that are used to send waste to landfill. This discourages the use of materials that can’t be recycled. |

Singapore South-East Asia is well known for its very high levels of marine plastic polluting. However, Singapore is not one of them. They have a range of public waste-management initiatives which result in 60% of waste getting recycled. The country offer grants to organisations developing new recycling technology and has plans to make companies report how much waste is not recycled. |

More Confident Investment Decision Making

Expect to make truly informed, risk-reduced decisions. 100% of our clients believe our platform has enabled them to “increase the speed of their early-stage research into new areas.”

Insights On Demand – in as little as 48 hours

You can access subject matter experts from anywhere in the world, whenever you need them. When technical challenges or commercial projects arise which need specific results, you can obtain valuable consulting recommendations from vetted Experts.

Commercially Effective Research

Your research capacity and capabilities are augmented through Pangea SI Experts – there is no need for hefty strategy/management consultancy retainers and you can forego the process of having to hire someone full time.

1

Clients notify us that they need leading insight for their project.

2

We engage and vet subject matter Experts matched to the request at speed.

3

Clients consult with their shortlisted Expert(s) and obtain forward knowledge to incorporate into their strategic plans.

4

Clients benefit from more refined analysis and practical recommendations to achieve a quantifiable business impact.