Explosives are used to break the rock to optimize fragmentation. Nowadays explosives are used in mining operations and civil works. The fragmentation (P80: fragment size at which 80 per cent of material passes) must be optimized according to the mine (loading equipment and crushers) and must be done a “mine to mill” project to minimize global cost and calculate P80 to optimize the process. Depending on the characteristics of the rock (basically UCS unconfined compressive strength) and the fracture spacing, the explosive is selected (ANFO, heavy ANFO, or emulsion). This selection is done to match explosive and rock impedance considering parameters such as VOD (velocity of detonation), explosive density, wave velocity of the rock Vp and rock density. In friable rock, with dry holes, ANFO can be used, and in competent rock, it must be used an explosive with more energy as heavy ANFO or emulsion.

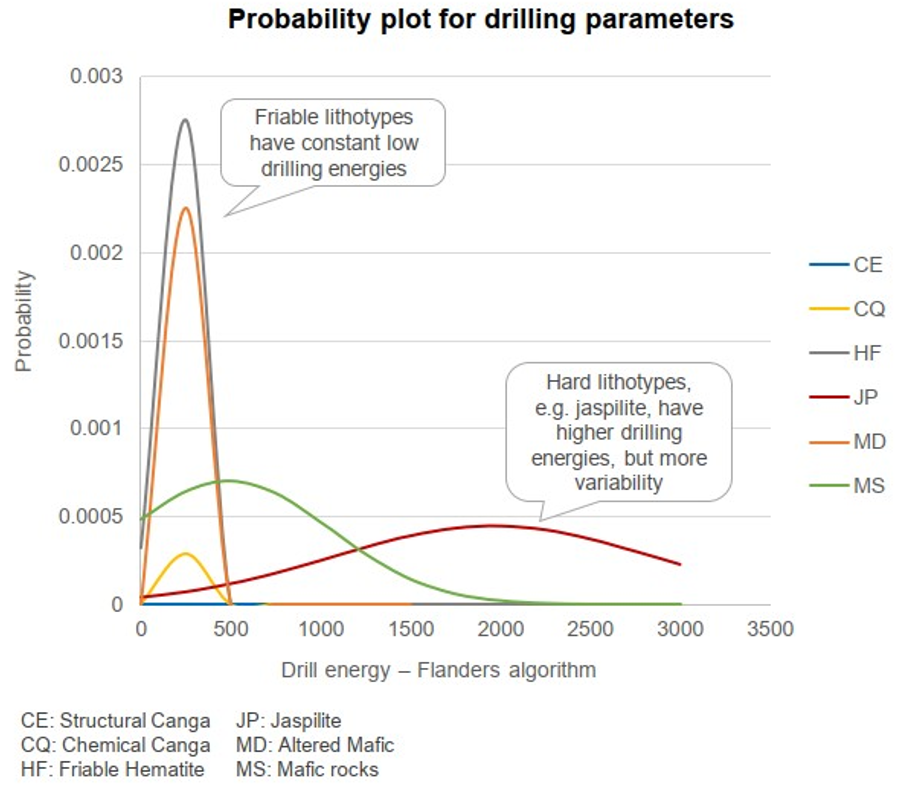

Even it is possible to change the explosive parameters according to the lithotypes. For example, in friable rocks, low-density explosives with low VOD, and in very competent rocks is required more energy with Al or other formulations to increase VOD and increase the fractures around the borehole. The selection of the explosive is done considering heave and shock energy and the challenge is to adjust the energy according to the MWD (measurement while drilling) in real-time, even at the same borehole.

Another challenge is the formulation. Nowadays the main raw material to produce explosives is ammonium nitrate. The emulsion is produced with oxidant salts (ammonium nitrate and other nitrates), and oil solution (hydrocarbon chains, and emulsifiers). Post Blasting some fumes happen to depend on the chemical reaction (CO2, CO, N2, H2O, NOx). Decarbonization is an agenda EGS (environment). The greenhouse gases must be controlled and reduced.

The Integrated Quality Management (IQM) solution moves operations from reactive to proactive practices by increasing orebody knowledge. The IQM proposition aims to greatly improve early geological understanding (by improving orebody knowledge through multiple techniques such as blasthole assaying) and maintain the integrity of this information across the value chain, reducing variability from Mine to Port.

In order to improve geological understanding the IQM proposition aims to amend current practices by moving from reactive face mapping and channel sampling to a proactive approach where sampling, modelling and tracking occur throughout the value chain to increase transparency.

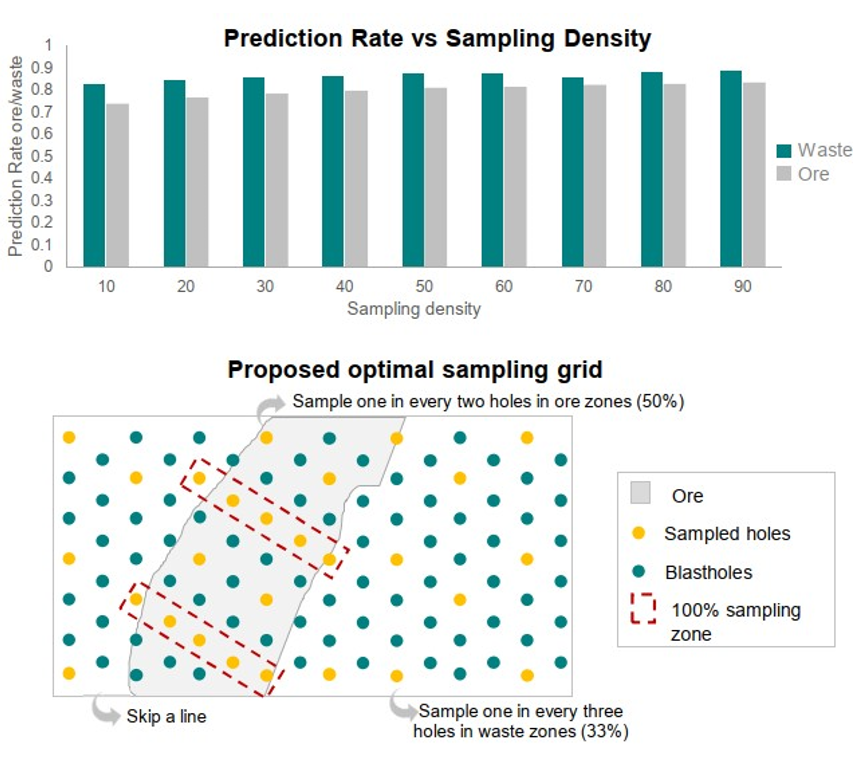

Blasthole assays provide geochemical data that enables the distinction of lithotypes and increases the accuracy of actual lithological contacts against the current short-term geological model. Through drill parameters from test polygons, it was possible to distinguish some lithologies from the energy intensity applied during the drilling process. The energy information from the boreholes contributes to the refinement of the geological model exposing contact zones.

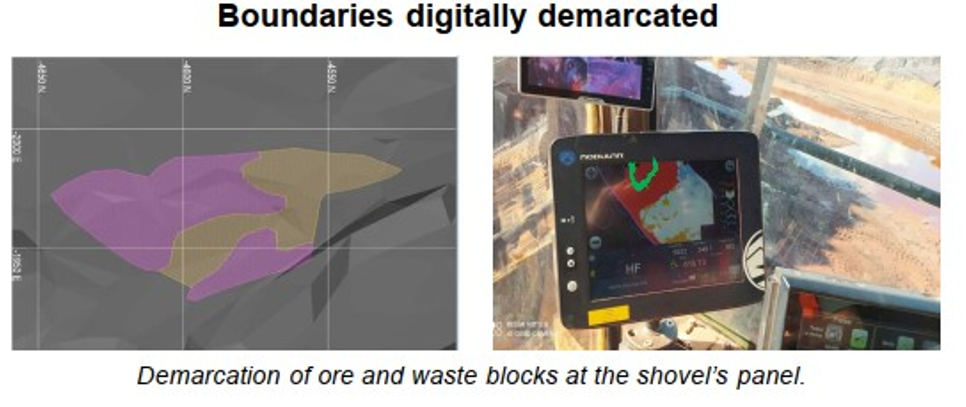

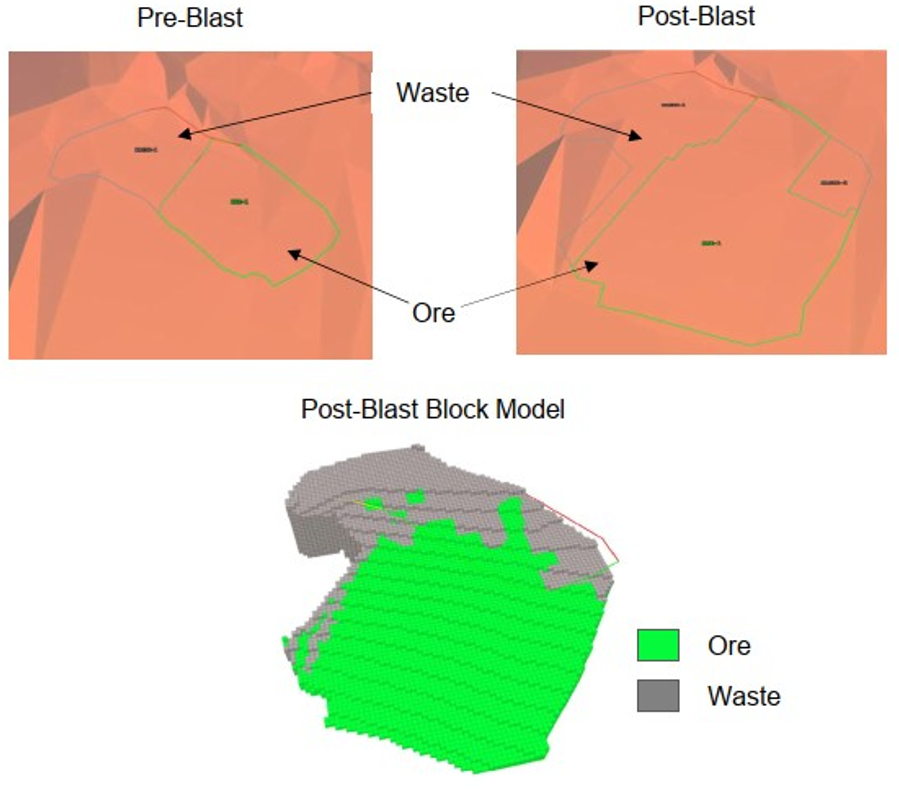

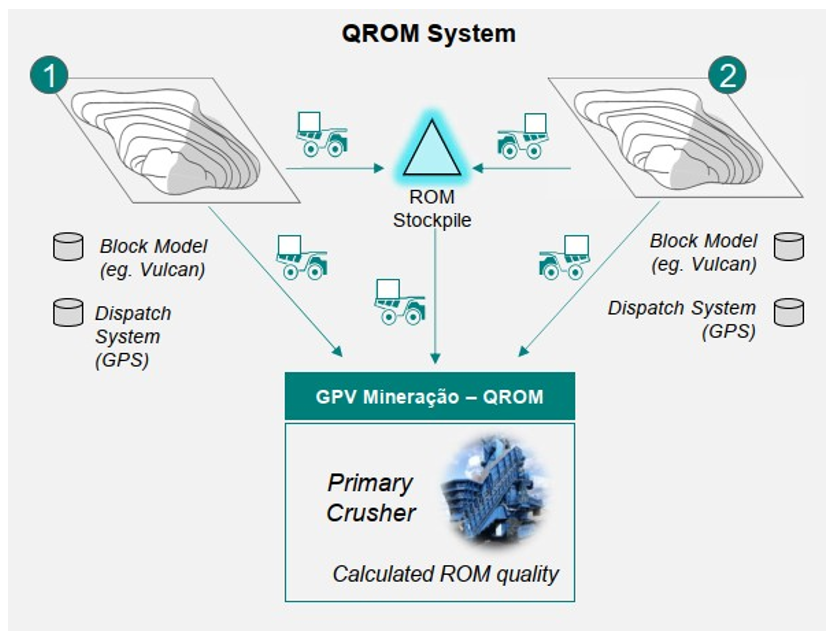

Usual blast practices contribute considerably to dilution and ore loss. An inaccurate block model means significant ore losses as ore are mistakenly sent to the waste stockpile and waste is sent to the plant. There are errors in the mining process that makes it difficult to actively differentiate ore & waste in the field. Demarcating boundaries in the field drives better compliance. Through the information of the current block model and the current fleet management/dispatch systems, it is possible to monitor and predict the plant feed. The Q-rom system will track and monitor the movement of material from the mine to the plant.

The Q-ROM system uses the information from the block model and associates it with the equipment cycle sent by the GPVM to calculate the ROM quality in the implementation phase. The main benefits of implementing the Q-ROM:

I. Dynamically monitor the quality of ROM and report more assertively the ROM quality sent to the crusher (new feed + stocks);

II. Monitoring the limits established for the ROM (main grades such as iron, SIO2, Al2O3 and PPC);

III. Proactively warn the plant about deviations from programmed ROM;

IV. Allow the operation to adjust the process according to the ROM characteristics, e.g., destinate the new feed to stockpiles;

It is possible to optimize the blending of the material used in the plant, through an accurate understanding of the physical, chemical and mineralogical characteristics of lithotypes. It is possible to predict productivity, considering the main feed and quality parameters. Some mine operations should consider different limits for quality parameters (IMH and PPC), due to limitations caused by the excess of moisture, for dry and wet seasons, respecting product quality specifications.

The digital boundary demarcation can provide better guidance to the shovel’s operator on the equipment, assisting with the appropriate destination of materials and improving the ore loss rates. Plant productivity can be accurately predicted based on historical data – parameters affect productivity.