The 3 fundamental types of explosives are mechanical, chemical and nuclear. A mechanical explosive is one that depends on a physical reaction such as overloading a container with compressed air, a mechanical device is often used in mining where a chemical reaction is undesirable.

A chemical explosive is a mixture that when subjected to heat, impact, friction, or detonation, it undergoes a rapid chemical change, involving large volumes of heated gases that exert pressure on a surrounding medium. A nuclear explosive is a device that from a nuclear reaction, releases a vast amount of energy that causes an explosion.

The 3 types of explosives that we will be focusing on are:

In recent years, the largest commercial application of explosives is mining, which has increased their usage in surface and underground mines. Whether the mine is on the surface or buried underground, blasting explosives are the most cost-effective way of displacing a large volume of material. Emulsion explosives have a lot of great advantages including safety and security, excellent resistance to water, increased velocity of detonation, transport, handling and storage, savings in drilling operations and low gas emissions.

The mining industry tends to use nitrate-based explosives such as emulsions of fuel oil and ammonium nitrate solutions, mixtures of ammonium nitrate prills (fertilizer pellets) and fuel oil (ANFO) and gelatinous suspensions or slurries of ammonium nitrate and combustible fuels.

Many factors contribute to increased sales of emulsion explosives. Developing countries are constantly on the quest towards rich materials through mining and quarrying. On the other hand, infrastructure projects like underground railways, road tunnels and construction projects all favour market growth.

Emulsion Explosives have been commercially available for over 50 years now and during this period, their popularity and production have been increasing year after year. In the process of manufacturing emulsion explosives, two basic pre-mixes are formed. The first comprises an aqueous solution of inorganic oxidizing salts, and the second, hydrocarbon fuel components, which provide the oil phase of the water-in-oil emulsion.

The unique feature of EE makeup is that they are insensitive to initiation and cannot sustain detonation without being sensitised. Due to this classification, the requirements for transporting EE matrices are much less stringent than the requirements for transporting traditional energetic materials. The simplistic transportation of emulsion explosives was the key factor underlying the development of bulk emulsion explosives.

The emulsion explosives market in India is expected to rise by 5.7% by 2028. A vast number of open mines in India use bulk emulsion explosives, with an annual use of around 550,00 tons per year. Some of the major projects in India include Transalpine railway tunnels and roads, and dams for hydroelectric power plants and power stations, with the number of major projects increasing year on year. The country’s emulsion explosives value is expected to reach over $159m by 2028.

Compared with India, the US is expected to rise at a steady rate by 2028, with around a 4.7% year-on-year growth by volume. This is mainly due to the country already being a leader in the market, so it is hard to achieve such growth. North American explosives producers are now looking at opportunities in the Latin American market, as there is a strong presence of precious metals such as lithium, silver and copper. This attracts significant investment from international mining companies, which is expected to increase demand for Bulk emulsion explosives.

The demand for emulsion explosives in China is expected to increase by a massive 6.2% by 2028, with the Chinese mining industry playing a substantial role in the Chinese economy. This is due to China being the world’s leading producer of steel, coal, aluminium, lead, rare earths, tin, zinc, tungsten and magnesium and other metallic minerals. The country’s emulsion explosives value is expected to reach over $262m by 2028.

NG dynamites possess poor safety properties during their manufacture transportation and use. For example, the use of dynamites is diminishing with time. Safer explosives such as emulsion explosives are gradually replacing them.

Volatility is the readiness with which a substance vaporizes. Excessive volatility often results in the development of pressure within rounds of ammunition and the separation of mixtures into their constituents. Volatility affects the chemical composition of the explosive such that a marked reduction in stability may occur, which results in an increase in the danger of handling.

Many explosives are toxic to some extent. Manufacturing inputs can also be organic compounds or hazardous materials that require special handling due to risks. The products, residual products or gases that make up explosives can be toxic, whereas others are harmless.

Using explosives when mining can cause a risk of entrapment following the collapse of a structure. Measures must be put in place to try and mitigate this risk and plans should be in place should this eventuality arise.

The mining explosives industry’s development rate has been significantly boosted by the surging demand for minerals and metals worldwide. Mining explosives are widely used in metal mining, quarrying, non-metal mining, and coal mining applications. Coal mining is one of the most important applications of mining explosives.

The accelerated use of coal as well as rare earth metals such as silver and gold along with earth minerals like bauxite and iron ore in diverse industries like chemical, automotive, and thermal will foster the need for extremely potent explosive products.

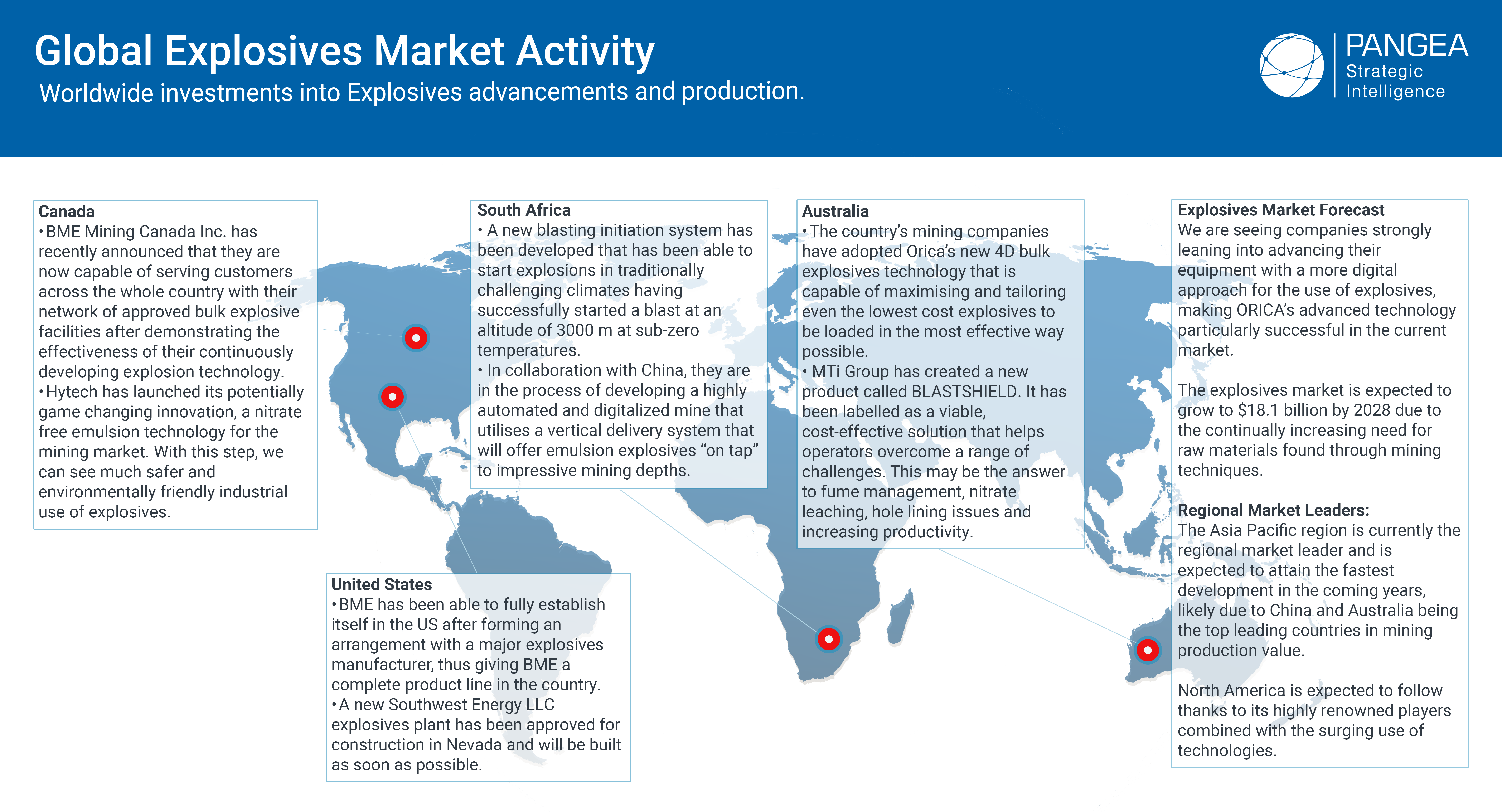

New and modern explosives technologies are compatible with both augured and pumped loading techniques across wet, dewatered, and dry hole conditions. Companies active in the mining explosives industry are focusing on enhancing their research capacities to develop more innovative technologies that can let mining customers carry out operations more precisely and efficiently. The combination of modern digital technology, explosives delivery technology, and formulation chemistry is providing great leverage to mining customers.

| ORICA Based in Australia, Orica is the world’s largest commercial explosives and blasting systems provider. The company specialises in providing blasting solutions to industries such as mining, quarrying, construction and oil and gas. With over $3.5B in revenues, they produce products such as bulk systems, electronic blasting systems, initiating systems, packaged explosives, and emulsifiers. |

Sasol Sasol is an integrated energy and technology company that develops and commercialises technologies with a dedication to sustainable development, proudly sharing that they source, produce and market their products sustainably. Their line of chemical business is not just limited to explosives, it also includes polymers, solvents and fertilisers. |

| Hanwha This company has diversified holdings but holds a successful involvement in explosives manufacturing. On top of manufacturing the torches for the 2018 Olympic games, they also secured a contract with Whitehaven Coal to supply all bulk and initiate explosives and down-the-hole services in Australia. |

MAXAMCorp MAXAMCorp offers high-tech products, some of the key ones being blasting solutions, cartridges and gunpowder, and raw materials for the nitro chemical industry. They also hold a speciality in demilitarisation by recycling explosives recovered from different sectors such as infrastructures, mining and demolitions. |

| BME Mining This company is a part of the Omnia group with a focus on the mining division of the company, with a business model oriented around long-term sustainability. While their product line may not be as extensive as other companies, they have a wide array of services including fly rock control, blast software, fragmentation analysis, down-the-hole full blasting services, and more. |

✓ Safety precautions when using explosives?

Explore the questions we can answer for you:

✓ How do explosives fit within my project?

✓ The mitigation of policy, regulation, and financing challenges.

✓ Specific explosive requirements by country.

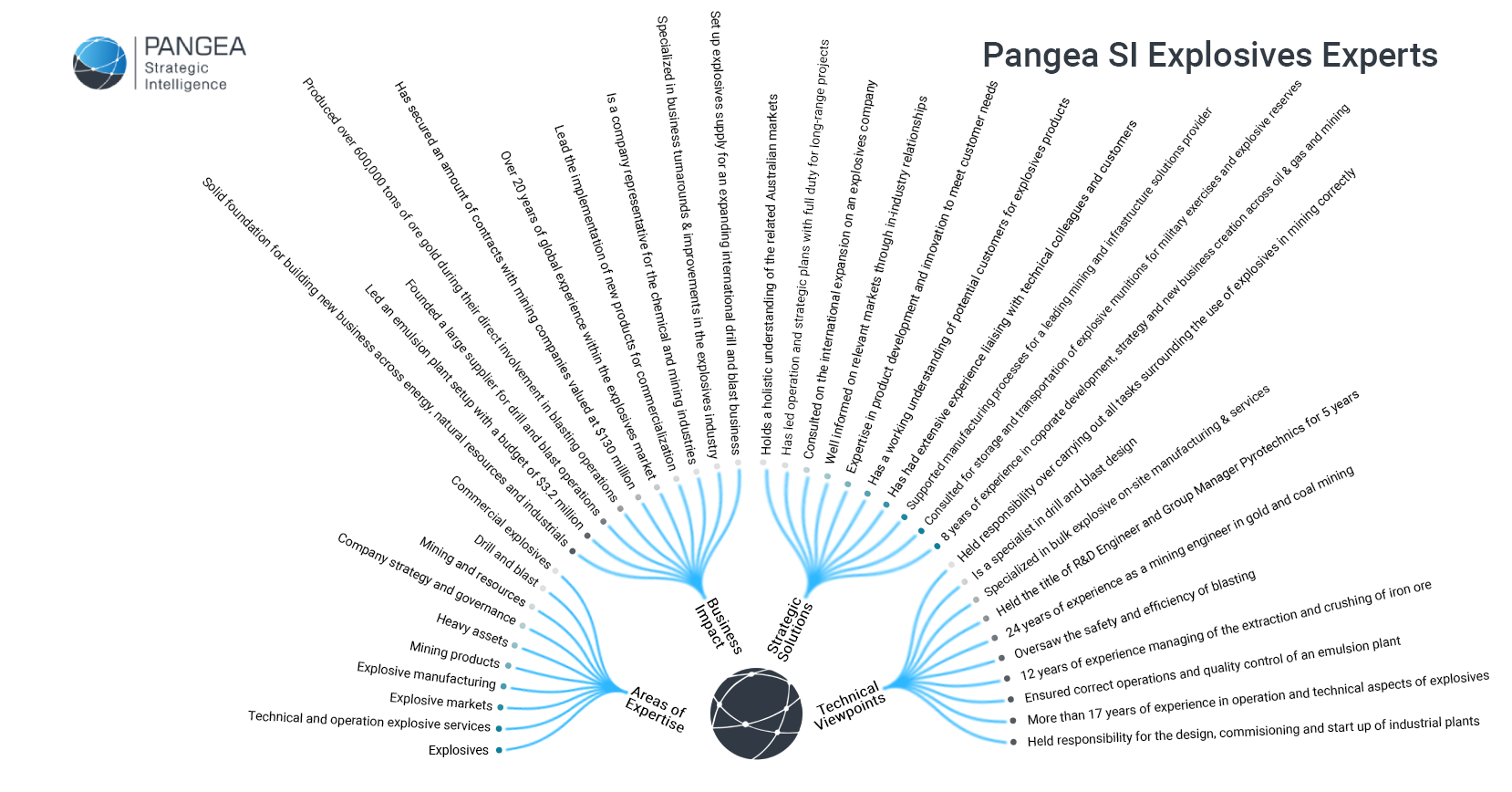

Clients notify us that they need leading insight for their project.

We engage and vet subject matter Experts matched to the request at speed.

Clients consult with their shortlisted Expert(s) and obtain forward knowledge to incorporate into their strategic plans.

Clients benefit from more refined analysis and practical guidance to achieve a quantifiable business impact.