Biomass exists in huge quantities around the planet and can be an efficient source of renewable energy and a competitive alternative to fossil fuels. But does it have a future or will other renewable sources outcompete biomass?

We had a discussion with some of our leading biomass experts to get their analysis and opinions on some of the biggest questions surrounding biomass. Get a better understanding of their knowledge and perspectives below.

Molecular Biology and Lipids Specialist: Depending on a direct technological aim. It could be promising to produce biomass from food wastes and technological wastes, e.g.- on poor soils, especially in view of present forestation and anti-desertification policies. Predominantly MENA region and other rich countries are concerned by food security. In the same paradigm of environmental technologies, biomass production could be promising via bioremediation of industrial wastes for soil renovation in developed economies such as Canada and the EU countries.

If it is about cost-effective production of maximal biomass volumes, from my point of view the most promising vector is aquaculture in warm climates. This could be established soon: aquaculture enables biomass production in volume, not on the surface; aquaculture is zero energy-consuming for heating, aquaculture costs zero for the land leases and is not sensitive for the quality of soils. Additionally, there are already existing technologies for processing sea-produced biomass in fields of food production as well as medicine.

Biomass and Plasma Technologies Researcher: Due to the increasing interest in generating hydrogen in a more cost-effective way, gasification is one of the most promising methods in the biomass industry.

Depending on the process itself, gasification produces synthesis gas that is a mixture, containing hydrogen, methane, and carbon monoxide.

The other promising technology is pyrolysis of biomass to produce liquid oil. The oil can be blended with liquid fossil fuels or be fractionated to produce speciality chemicals. Another promising technology is the use of plasma technology for reforming biogas or syngas to chemicals or liquid fuel.

Chemical Engineer and Researcher: As a shift toward a sustainable future, the realization of the bio-economy is getting an irresistible approach. Technology improvements are rising from laboratory to industrial scales and this trend is expected to increase. Biomass – as a source of carbon and hydrogen – is any organic matter that can be available on a renewable or recurring basis. Inherent in the definition of biomass, its availability is a key factor if it is going to be used as an energy source or synthesis of chemicals and building blocks. From a biorefinery point of view, the most available types of biomass are:

• Energy crops: densely planted with high yield which are planted dedicatedly to supply a huge amount of biomass to a refinery, for any purpose. Examples of these energy crops are sugar cane in Brazil (targeted for ethanol production) and oilseed rape in Europe (for biodiesel production).

• Waste and residue from the agricultural sector: any residue from the agricultural fields that are not used for commercial purposes. The residues from the pulp and paper industry or animal manure are also placed in this category.

• Forestry residues: any waste or non-harvested biomass left behind in commercial wood stands, or from forest management operations.

• Industrial and municipal waste: municipal solid waste and sewage sludge, or industrial waste. Paper, cardboard, food leftovers, wood, and yard waste are all biomass.

But how biomass is used, let´s say, converted, to plastics, polymers, fuels, chemicals, and any other material that is currently based on fossil resources? In a general classification, four types of conversion routes can be named i.e., combustion, gasification, pyrolysis, and anaerobic digestion. The latter is the most mature technique that is used in a large number of energy recovery industries. The organic matter is broken down by bacteria to produce a methane rich biogas. The other three are thermochemical conversion routes that are applied either to recover the energy directly from biomass for further applications (heat, electricity, or both) or to produce syngas (mixture of hydrogen and carbon dioxide) for further synthesis of important primary chemicals such as methanol. Bio-oil is a product of pyrolysis that depending on the type of pyrolysis and the catalysts used can directly yield gasoline range fuels or olefins.

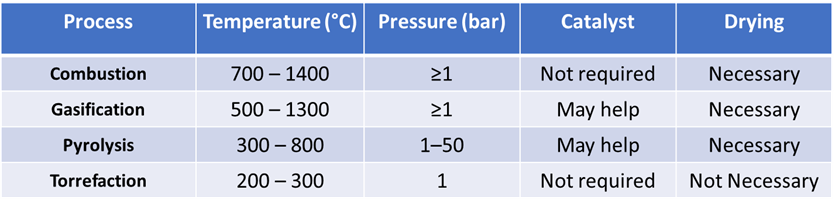

Combustion (900-1400 ᵒC) of biomass is the most widely used technology to generate power. However, the combustion efficiency is lower compared with gasification and pyrolysis and may need extensive and costly gas treatment. Emissions from biomass combustion can be more contaminating than coal combustion if insufficient gas treatment is applied. Biomass gasification (800-1300ᵒC) is mostly used to generate syngas that can be used for liquid biofuel production via further downstream processes such as Fischer-Tropsch. Besides, it may be used to generate bio-methane or methane-rich biogas. The pyrolysis (500-800ᵒC) of biomass is a very promising, efficient, and economically viable technology that can be well controlled and optimized toward targeted products. Pyrolysis products and fraction of hydrocarbons especially in the bio-oil strongly depend on the choice of catalyst, final temperature, and heating rate. As an emerging and promising technology, torrefaction is a controlled and very slow pyrolysis route via which biomass in any heterogenous state can be converted to a high heating value (similar to coal), homogenous, and carbon-rich solid with improved physical properties which is ideal for further combustion or gasification. During the torrefaction process (below 300ᵒC and at ambient pressure), biomass undergoes a kind of devolatilization which leads to 40% weight loss but keeping 90% of its energy content. A very brief comparison of different thermochemical conversion technologies of biomass is given in the following table:

Molecular Biology and Lipids Specialist: Definitely, pollution by persistent and radioactive pollutants, heavy metals etc. Being highly bioaccumulative, these substances are able to spoil huge volumes of biomass and are hard to eliminate, endangering the whole industry, independently of the technology chosen. Pollution affects soils, waters, and even reactor-produced biomass.

Biomass and Plasma Technologies Researcher: The economics of the biomass industry. As countries decarbonize, demand for biomass may increase, thus increasing the price of biomass. The cost may be subsidized by a carbon tax, but this carbon tax may be passed on to the consumers, depending on each country’s policy. In some countries, economic stimulus packages for post-pandemic recovery may dry up public investments into decarbonization initiatives, or even derail energy transition policies. Therefore, alternative financing of bioenergy projects may be required.

The solution might be digital – can cryptocurrencies or digital ‘green bonds’ be used to raise funding, based on the potential amount of carbon mitigated? If so, how will the biomass industry cope with the volatility of projects raised by cryptocurrencies?

Chemical Engineer and Researcher: Biomass is very diverse in nature and depending on the type of biomass and its source, it can possess very different thermophysical and chemical properties. Even the same type of plants from two different regions in the same country can be very different in properties as the type of soil and climate are not similar! Adding that biomass is made up of carbon, hydrogen, oxygen, nitrogen, sulfur, and a variety of minerals, the complicacy of the conversion processes and treatment of the final products can be explained. With that said, the conversion processes and the design of the reactor and operating systems depend on the chemical and physical properties of biomass. Therefore, the flexibility of the operation with different types of biomass in the same plant may be very complicated or even impossible. For example, it can be impossible to handle the seasonal variations in the type of biomass. Another controversial issue around the use of energy corps is the land use for energy versus food, which soon may cause serious conflicts as the world energy and food demands are sharply increasing.

In the case of municipal solid waste, the issue remains in the hazardous emissions via flue gases – especially for gasification and combustion – which require extensive and expensive gas treatment. According to rigid environmental measures, halogenated compounds must be decomposed within the process to prevent emissions into the atmosphere. This may exert a huge cost on the gas treatment operations of the plants as high as 35% of the total operating cost. An alternative to conventional incineration and gasification plants is oxy-combustion where a mixture of oxygen and carbon dioxide is introduced into the system instead of air. As a result, very high temperatures (up to 1400ᵒC) are reached where hazardous compounds are decomposed and gas treatment via filtration is carried out with higher efficiency. However, the technical complicacy of oxy-combustion of heterogenous waste hinders its scale-up and further development. From the technical point of view, in the case of gasification, the formation of tars (aromatics) and particles of alkali metals (abundant in any type of biomass) is the technology bottleneck. There are very corrosive and cause serious damages to the reactor, boiler, and tubing systems. Besides, alkali compounds may cause slagging or decrease the efficiency in heat exchangers if power generation is intended. Overall, among the thermochemical routes pyrolysis and torrefaction are more promising in terms of technological, economical, and efficiency benefits. It is possible to get a very high share of bio-oil (up to 70w%) if the process is well controlled. Again, the composition and the source of the biomass must be well controlled to preserve the quality of the product.

Renewable Energy Finance and Emerging Markets Expert: To obtain financing for these types of projects. I think that technologies need to mature (in biomass the quality of the input material is very important for the operational efficiency of the plant) but financing entities are still a bit reluctant to finance such business because they do not want to assume the related technological complexity (potential operational risks). Anyhow, alternative financing sources are currently available and probably will help a lot of biomass projects to become realized. Related to this it is also very important to have proven and reliable EPC contractors, matured technology (proven track record, manufacturer guarantees, etc.), and an experienced O&M operator.

Molecular Biology and Lipids Specialist: The answer depends on the direct aim. Phytoplankton is well-fitting for the objective, nevertheless “cleanest” could mean the quality of the biomass by itself or sustainability & carbon footprint of its production. In this way aquaculture again gives benefits by low regulation culture in the state of art. On the other hand, if talking about carbon fixation in biomass as the industrial approach it could be attractive to breed fast-growing plants, an additional benefit- to apply obtained biomass in furniture, tableware production etc. without forest impact.

Biomass and Plasma Technologies Researcher: This is a difficult question to answer as biomass is such a diverse resource. The type of biomass is regionally dependent on agricultural activity and industry.

Biomass used for the Scandinavian countries may not be abundant in East Asia, and vice-versa. In some cases, biomass has to be imported, shipped from another country to the point of use.

The most widely used biomass so far is woody biomass and palm kernel shell. Palm kernel shells are produced from the palm oil industry and is being imported & used by East Asia. Both have high enough lower heating values and low ash contents.

Chemical Engineer and Researcher: Considering the “clean or efficient” sources of biomass, the chemical and physiochemical properties of the biomass together with the applied conversion technology should be taken into account. Municipal solid waste and industrial waste are very abundant (no issue with renewability index like energy corps) but may contain very hazardous contaminants such as chlorine and mercury (in any form and structure). In this sense, they are considered a very contaminated types of biomass that may directly affect the public acceptance aspects of the technology. However, if incineration at a high temperature (> 1100ᵒC) is applied, full decomposition of hazardous compounds can be reached. In the case of forestry and agricultural waste, and energy corps the fraction of minerals plays an important role. Higher mineral content (Si, K, Na, Ca, etc) negatively affects the quality (carbon fraction i.e., the heating value) of biomass and may cause more complicacy during the conversion processes as more tars and alkali compounds are formed. As mentioned, the choice of the thermochemical process is also important. For example, special gasifier designs (known as downdraft gasifiers) results in high tar cracking and cleaner gas production. if pyrolysis is applied, it is possible to maintain a significant share of impurities in the gas or solid phase and produce a cleaner bio-oil.

The successful implementation of biomass as a sustainable resource especially for energy generation purposes must meet the crossroad of environmental (renewability index), technological (process design), societal (availability and public acceptance)., and economical aspects. The choice of the available biomass and the right conversion routes is a trade-off between the properties of the biomass, the process cost, emissions, and the quality and type of the targeted product.

Pangea Strategic Intelligence has several leading Experts who can guide clients through the nuances of biomass and the biomass market.