Battery manufacturing involves intricate processes to create different battery types, such as lithium-ion, solid-state, and flow batteries. The production of batteries comprises key components like cathodes, anodes, and electrolytes, each with its specific manufacturing requirements. Traditional battery manufacturing techniques have been effective but often face challenges in terms of scalability, cost, and environmental impact. However, emerging manufacturing techniques such as additive manufacturing (3D printing) and roll-to-roll processing offer promising alternatives. These innovative approaches can streamline production, improve customization, and enhance efficiency, paving the way for advanced battery manufacturing.

Materials play a crucial role in determining battery performance and characteristics. The ongoing research in battery materials aims to enhance energy density, cycle life, safety, and cost-effectiveness. Researchers are exploring advanced materials for cathodes, anodes, and electrolytes to improve battery performance. For example, materials like lithium iron phosphate (LiFePO4) and silicon-based anodes are being investigated for their higher energy density and longer lifespan. Additionally, sustainable, and eco-friendly materials, such as sodium-ion and organic materials, are gaining attention for their potential in reducing the environmental impact of batteries. The continuous development of advanced materials holds the key to unlocking the next generation of high-performance and environmentally friendly batteries.

Enhancing battery performance and safety is a top priority for battery manufacturing R&D. Researchers are working on various fronts to address challenges such as energy density, cycle life, and charge rate. Advances in materials, including novel cathode and anode materials, electrolyte formulations, and improved electrode designs, are being pursued to optimize battery performance. Moreover, research efforts are focused on developing advanced battery management systems and monitoring technologies to ensure safe operation and prevent issues like thermal runaway. These advancements make batteries more reliable, longer-lasting, and safer, enabling their integration into diverse applications.

The scalability and cost-effectiveness of battery manufacturing are critical factors for widespread adoption. Increasing production capacity while maintaining quality and efficiency poses challenges for conventional manufacturing processes. Researchers are exploring innovative manufacturing techniques and process optimizations to address these challenges. Techniques such as roll-to-roll processing, where battery components are fabricated on continuous rolls, enable high-volume production with reduced manufacturing costs. Additionally, automation and machine learning advancements are being utilized to streamline production and reduce labour costs. Furthermore, the development of recycling technologies and second-life applications can improve sustainability and reduce costs associated with battery manufacturing.

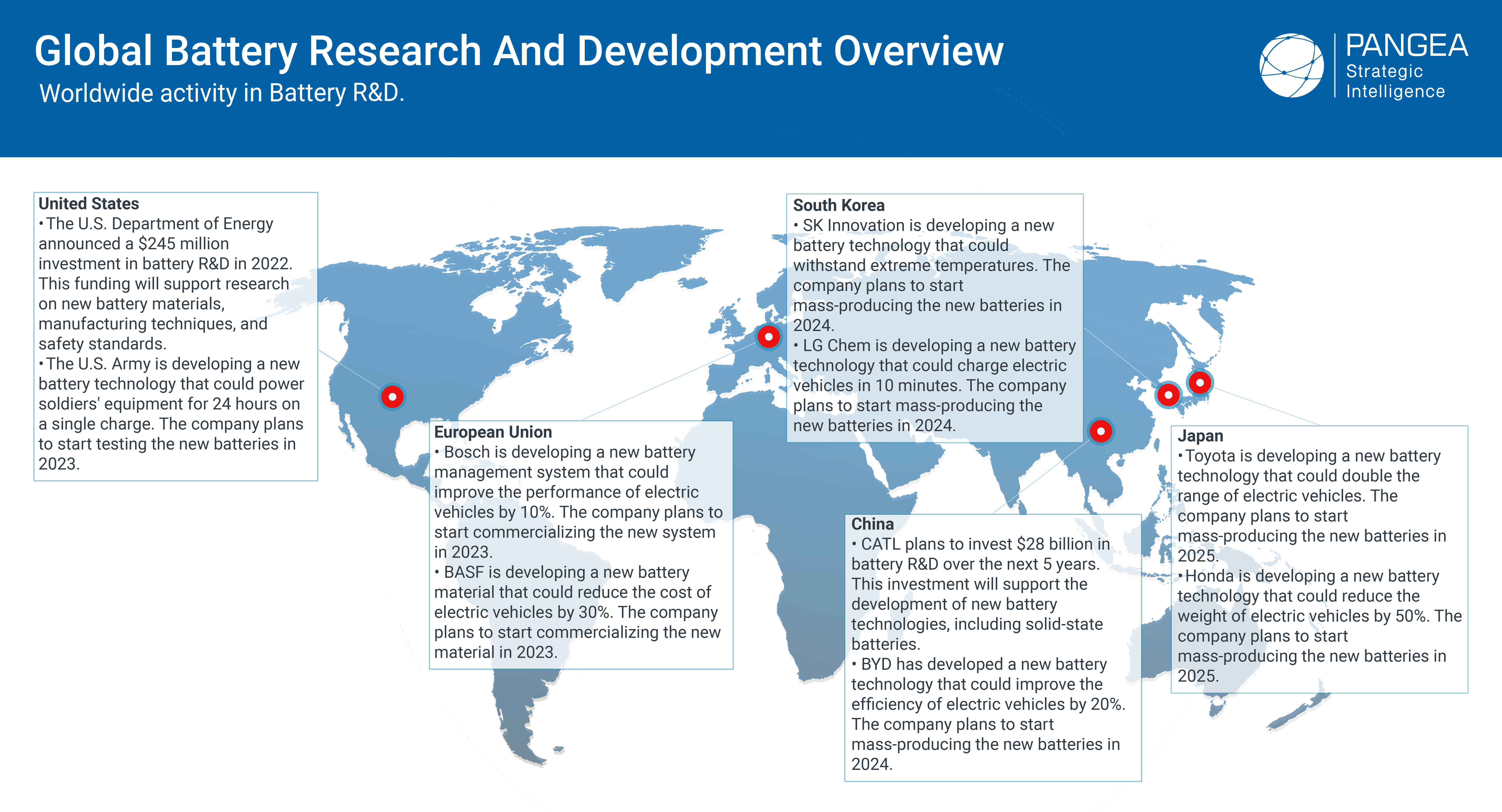

Battery manufacturing R&D thrives on collaborations between academia, industry, and government agencies. Collaborative research efforts leverage expertise from different fields to tackle complex challenges and drive innovation. Additionally, industry-led initiatives and partnerships play a crucial role in advancing battery manufacturing technologies. These initiatives bring together companies, research institutions, and government entities to foster knowledge exchange, resource sharing, and joint investments. Successful collaborations and industry initiatives have already yielded significant advancements in battery technology and hold great potential for further breakthroughs in the future.

| Project Title |

Institution/Organization |

Location |

Description |

| Solid-State Battery Research |

Toyota Motor Corporation |

Japan |

Toyota is conducting research on solid-state batteries, which offer higher energy density, improved safety, and faster charging compared to conventional batteries. |

| Next-Generation Lithium-Ion |

Tesla, Inc. |

United States |

Tesla is focused on developing next-generation lithium-ion batteries with advancements in energy density, longevity, and cost reduction to enhance electric vehicle performance. |

| Sodium-Ion Battery Development |

University of Oxford |

United Kingdom |

The University of Oxford is actively researching sodium-ion batteries as a potential alternative to lithium-ion batteries, exploring their viability and performance characteristics. |

| Silicon-Anode Battery Research |

Stanford University |

United States |

Stanford University is conducting research on silicon-based anode materials for batteries to increase energy density, extend battery life, and improve overall battery performance. |

| Advanced Flow Battery Systems |

Harvard University |

United States |

Harvard University is involved in the development of advanced flow battery systems, which offer scalable energy storage solutions for renewable energy integration and grid applications. |

| Sustainable Battery Materials |

Swedish Energy Agency |

Sweden |

The Swedish Energy Agency is driving research on sustainable battery materials, focusing on environmentally friendly alternatives that minimize the use of critical resources and reduce environmental impact. |

| Aluminium-Air Battery Research |

National University of Singapore |

Singapore |

The National University of Singapore is engaged in research on aluminium-air batteries, aiming to develop high-energy-density batteries for electric vehicles and portable electronics. |

The future of battery manufacturing research and development is promising, with several emerging trends on the horizon. One such trend is the development of solid-state batteries, which offer higher energy density, improved safety, and wider temperature tolerance compared to conventional lithium-ion batteries. Another trend is the integration of artificial intelligence (AI) and machine learning in battery manufacturing, enabling real-time optimization, quality control, and predictive maintenance. Furthermore, advancements in battery manufacturing will impact various industries, including electric vehicles, renewable energy storage, and portable electronics, accelerating the transition to a cleaner and more sustainable energy future.

Battery manufacturing research and development play a crucial role in shaping the future of energy storage. The advancements in manufacturing techniques, materials, performance, and safety are driving the evolution of batteries, making them more efficient, reliable, and environmentally friendly. With collaborations between academia, industry, and government, along with industry-led initiatives, the pace of innovation in battery manufacturing R&D will accelerate. As we continue to invest in this crucial field, the world can look forward to advanced energy storage solutions that power our lives while minimizing environmental impact.

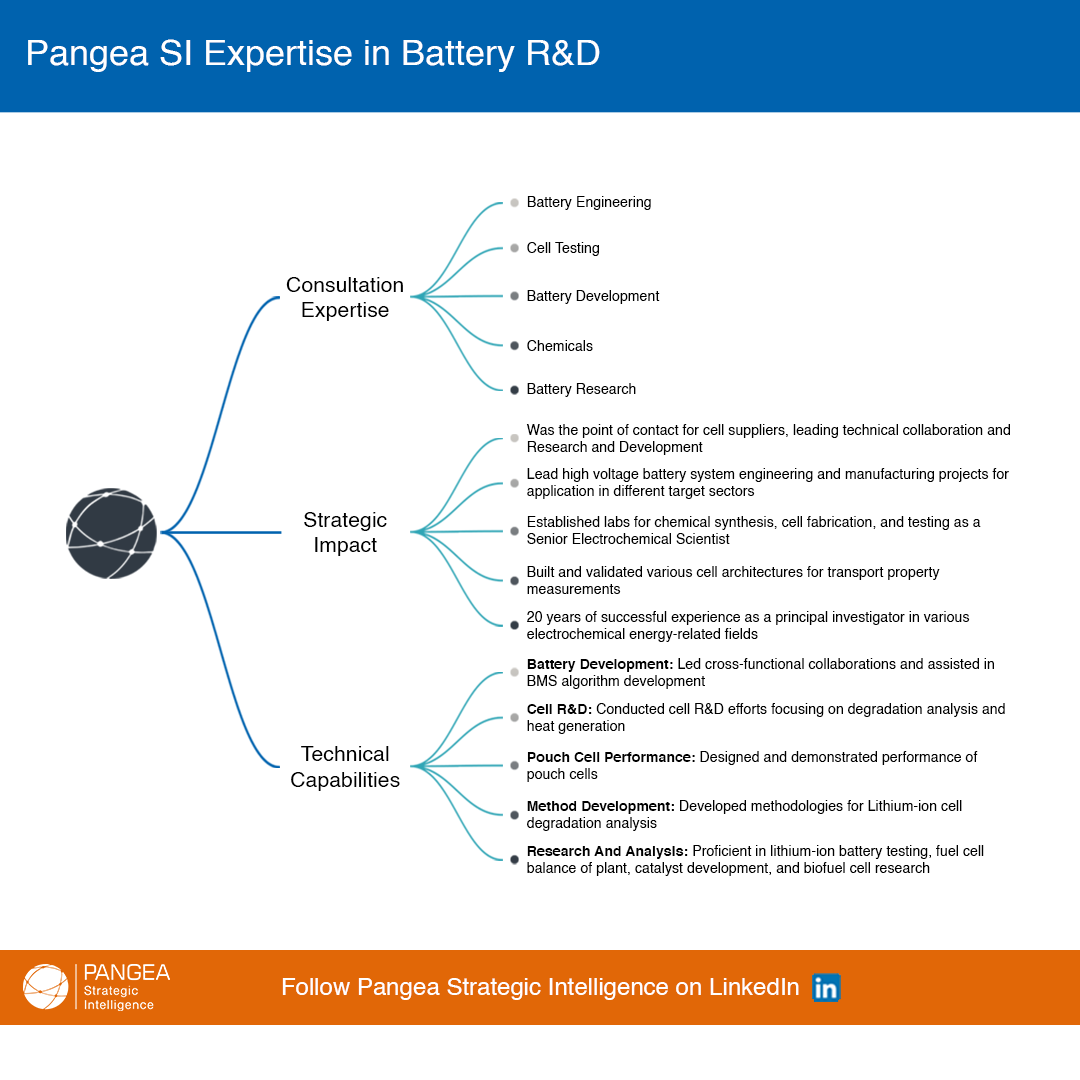

Clients notify us that they need leading insight for their project.

We engage and vet subject matter Experts matched to the request at speed.

Clients consult with their shortlisted Expert(s) and obtain forward knowledge to incorporate into their strategic plans.

Clients benefit from more refined analysis and practical guidance to achieve a quantifiable business impact.